A heat exchanger is a device specifically designed to transfer heat from one fluid to another without allowing the two fluids to mix. This process is widely used across many industries, including manufacturing, energy production, HVAC, food processing, and chemical engineering. Modern industrial solutions, such as those highlighted on see more, focus on maximizing heat transfer efficiency while maintaining durability and operational safety.

The Basic Working Principle of a Heat Exchanger

The fundamental purpose of a heat exchanger is simple: move heat from a hot medium to a cooler one. This is achieved by separating the fluids with a solid surface, usually made of metal due to its excellent thermal conductivity. As the hot fluid flows along one side of this surface, heat passes through the material and is absorbed by the cooler fluid on the other side.

The two fluids can be liquids, gases, or a combination of both. Since they never come into direct contact, heat exchangers are ideal for applications where hygiene, safety, or chemical separation is essential.

How Heat Transfer Occurs

Heat exchangers rely on three main modes of heat transfer:

Conduction occurs when heat passes through the solid wall separating the fluids. Metals such as stainless steel or titanium are commonly used because they conduct heat efficiently.

Convection takes place when heat is transferred between the fluid and the surface of the heat exchanger. Faster fluid movement usually increases heat transfer efficiency.

Temperature difference drives the entire process. The greater the difference between the hot and cold fluids, the more effective the heat exchange will be.

The design of the exchanger aims to optimize all three factors to achieve maximum performance.

Types of Heat Exchangers

There are several heat exchanger designs, each suited to specific operating conditions:

Plate Heat Exchangers

Plate heat exchangers consist of multiple thin metal plates pressed together. The plates create channels through which hot and cold fluids flow alternately. This design offers a large surface area in a compact space, resulting in high thermal efficiency. They are commonly used in HVAC systems, food and beverage processing, and pharmaceutical production.

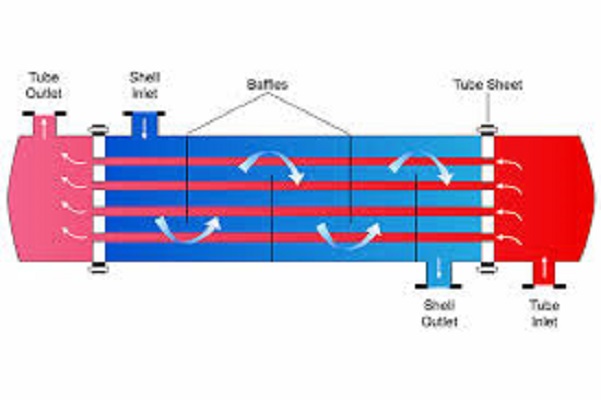

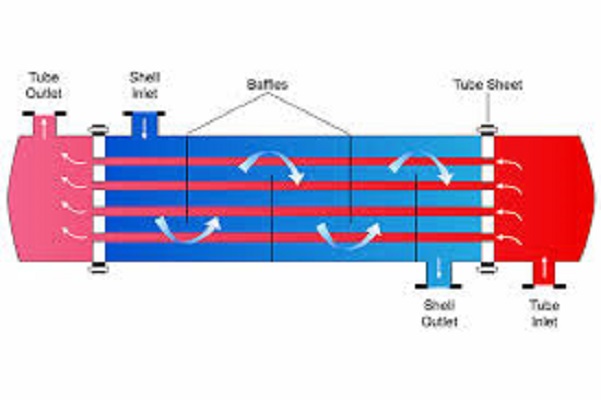

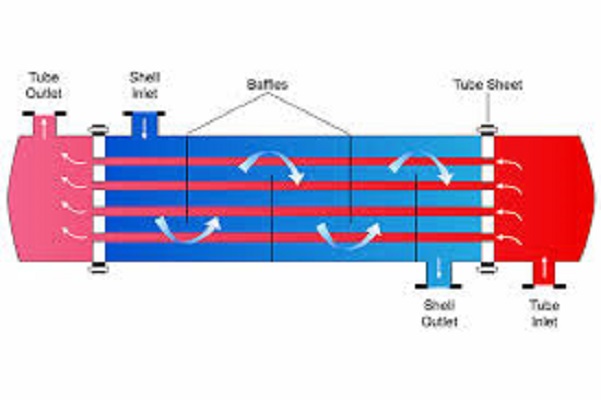

Shell and Tube Heat Exchangers

This traditional design features a series of tubes enclosed within a cylindrical shell. One fluid flows through the tubes, while the other flows around them. Shell and tube exchangers are known for their strength and are often used in high-pressure and high-temperature environments such as oil refineries and power plants.

Air-Cooled Heat Exchangers

Instead of using water, these exchangers rely on ambient air to cool fluids. Fans force air over finned tubes, making them suitable for locations with limited water availability.

Flow Configurations and Efficiency

The way fluids flow through a heat exchanger significantly affects its performance. There are three main flow arrangements:

- Parallel flow, where both fluids move in the same direction

- Counterflow, where fluids move in opposite directions

- Crossflow, where fluids move perpendicular to each other

Counterflow heat exchangers are generally the most efficient because they maintain a consistent temperature difference along the entire length of the exchanger.

Why Heat Exchangers Matter in Industry

Heat exchangers play a vital role in improving energy efficiency. By recovering waste heat and reusing it elsewhere in a system, they help reduce fuel consumption and operating costs. This not only saves money but also lowers environmental impact by reducing emissions.

They also enhance process control by maintaining stable temperatures, protecting equipment from thermal stress, and extending the lifespan of industrial machinery.

Maintenance and Reliability

Proper maintenance is essential for ensuring long-term heat exchanger performance. Regular cleaning prevents fouling and scaling, which can significantly reduce heat transfer efficiency. Components such as gaskets, seals, and plates must be inspected periodically to prevent leaks and maintain safety.

Well-maintained heat exchangers provide reliable operation, minimal downtime, and consistent thermal performance.

Conclusion

A heat exchanger works by transferring heat between two fluids through a solid surface using the principles of conduction, convection, and temperature difference. With various designs available—such as plate, shell and tube, and air-cooled exchangers—these devices can be adapted to almost any industrial or commercial application. Their efficiency, versatility, and reliability make heat exchangers an indispensable part of modern engineering systems.

- What are the Advantages of Plate Heat Exchangers in Modern Industries?

In today’s fast-evolving industrial landscape, efficiency, sustainability, and cost control are more important than ever.… Read more: What are the Advantages of Plate Heat Exchangers in Modern Industries?

In today’s fast-evolving industrial landscape, efficiency, sustainability, and cost control are more important than ever.… Read more: What are the Advantages of Plate Heat Exchangers in Modern Industries? - Resin Bonded Surfaces: Best Uses and Advantages for Residential Driveways and Gravel Surfacing

Choosing the right surface for a residential outdoor space is about more than just looks… Read more: Resin Bonded Surfaces: Best Uses and Advantages for Residential Driveways and Gravel Surfacing

Choosing the right surface for a residential outdoor space is about more than just looks… Read more: Resin Bonded Surfaces: Best Uses and Advantages for Residential Driveways and Gravel Surfacing - Family-Friendly Living in Singapore: Balancing Homes with Educational Access

Choosing a home in Singapore involves more than lifestyle and design—it also requires thoughtful consideration… Read more: Family-Friendly Living in Singapore: Balancing Homes with Educational Access

Choosing a home in Singapore involves more than lifestyle and design—it also requires thoughtful consideration… Read more: Family-Friendly Living in Singapore: Balancing Homes with Educational Access - Vertical Blinds Installation in Sydney for Long-Lasting Comfort and Style

Introduction Window coverings are more significant than most people think when it comes to improving… Read more: Vertical Blinds Installation in Sydney for Long-Lasting Comfort and Style

Introduction Window coverings are more significant than most people think when it comes to improving… Read more: Vertical Blinds Installation in Sydney for Long-Lasting Comfort and Style - How Does a Heat Exchanger Work?

A heat exchanger is a device specifically designed to transfer heat from one fluid to… Read more: How Does a Heat Exchanger Work?

A heat exchanger is a device specifically designed to transfer heat from one fluid to… Read more: How Does a Heat Exchanger Work?

What are the Advantages of Plate Heat Exchangers in Modern Industries?

Resin Bonded Surfaces: Best Uses and Advantages for Residential Driveways and Gravel Surfacing

Vertical Blinds Installation in Sydney for Long-Lasting Comfort and Style

How Does a Heat Exchanger Work?

How Does a Heat Exchanger Work?

Why Should You Choose Vela One for Your Next Home or Investment?

The New ARGUS G3 mini with iCOSM CODE 2.0: Power and Portability in an Ultra-Light 40.85 g Design